Introduction :

This machine is specially designed for liquid product (or other kinds of semi-liquid products, such as water, juice, yogurt, wine, milk etc. ) to be filled and sealed inside empty plastic cups. This filling and sealing machines applied with world famous electrical and pneumatic components. All the parts of machine contact with powder are made of stainless steel and food grade plastic tubes.

It is convenient and reliable. It is a kind of program-controlled machine that is universal and functional. Features are compact structure, high automation, easy to use, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work. Components (e.g. Stainless steel, aluminum, copper and other corrosion-resistant) are in line with Food Hygiene Law.

Main Performance and Features :

1. English and Chinese screen display, operation is simple.

2. PLC computer system, function is more stable, adjustment any parameters not need stop machine.

3. Adopted with wheels to conveniently move.

4. Temperature independent control system ,precision get to ±1℃.

5.Hopper easy to open and close to conveniently clean.

6. Three emergency stop buttons to keep production safe.

7. Piston filling type with leak-proof nozzles.

8. Storage air tank to keep production more stable.

| Work Process | # Empty cup loading | Cups stack together, loading one by one, pneumatic type, 2 columns in total. |

| # Filling | Piston filling type with leak-proof, volume can be adjusted easy, all parts contact with yogurt are made of SUS-304 and food grade tubes. | |

| # UV sterilization | Sterilize cups and products. | |

| # Foil loading | Pick and place foils on filled cups by silicone suctions, 2 columns in total. | |

| # First sealing | 2 copper sealing heads, temperature can be adjusted, pneumatic sealing type. | |

| # Second sealing | 2 copper sealing heads, temperature can be adjusted, pneumatic sealing type. | |

| # Second sealing | Pick cover by suction and press. | |

| # Finished cups pushing out | Finished cups automatic pushing out. | |

| Optional

Features |

Frame made of stainless steel | All the parts will be made of stainless steel, aluminum and copper. |

| Air clean system | Keep cleaned air move in the area of machine. | |

| Open door detector | When the dust cover opened by worker, this machine stop, can be suspended. | |

| No cups detector | No cup, machine stop. | |

| Finished cups picking out | … | |

Data of the machine

| Voltage | 220v/380v 50-60Hz |

| Power | 9500w |

| Speed: | 8000-10000 cups/h |

| Fill Range | 50ml-400ml |

| Filling accuracy | ±1.5% |

| Temperature Range: | 0-300 ℃ |

| Machine Size | 4100mm*1200m*1900mm |

| Machine Weight | 1500kg |

| Date Printer | Included |

| Package | Wooden box |

|

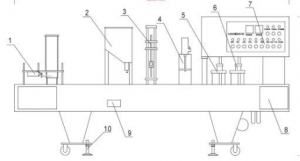

Structure |

||||

| 1 | Cups loading station | 6 | Second sealing | |

| 2 | Filling hopper | 7 | Control box | |

| 3 | Filling station | 8 | Driving station | |

| 4 | Foils loading station | 9 | Liquid waste exit | |

| 5 | First sealing | 10 | Supporting foot | |

| Material: The frame made of U-steel and antirust paint, then cover by SUS-304. | ||||

Detail Show of The Machine

|

Cup loading station |

|

|

Filling station |

|

|

Foil loading station |

|

Piston plunger |

|

|

Twice sealing |

|

|

Filled cup pushing out

|

Main Parts Brand

| NO. |

GOODS OF DESCRIPTION |

Brand |

| 1 |

PLC |

GERMANY SEMENS

|

| 2 |

TOUCH SCREEN |

GERMANY SEMENS |

| 3 |

Transducer |

GERMANY SEMENS

|

| 4 |

Cam box |

China |

| 5 |

VACUUM PUMP |

China |

| 6 |

MOTOR |

TAIWAN |

| 7 |

VACUUM FILTER |

China |

| 8 |

Air Switch |

FRANCE SCHEINDER |

| 9 |

Standby electric Relay |

FRANCE SCHEINDER |

| 10 |

DIGITAL PRESSURE SWITCH |

SMC SMC |

| 11 |

VALVE |

|

| 12 |

CYLINDER |

SMC |

| 13 |

Relay |

OMRON |

|

|

OMRON |

|

| 14 |

TEMPERATURE CONTROLLER

|

CHINA |

| 15 |

SUPULE |

GA |

| 16 |

CAM BEARING |

GA |

| 17 |

LINEAR BEARING |

GERMANY IGUS |

|

|

|

|

| 18 |

CLIP |

GA |

| 19 |

HEATING TUBE |

GA |

| 20 |

PRINT CODE |

GA |

| 21 |

PROXIMITY SWITCH |

OMRON |

TOOL BOX

|

Model of : GL-CFS12 |

||||||

|

No. |

Category |

Descriptions |

Unit |

Amount |

|

Note |

|

1 |

Technical Document |

Main Machine |

set |

1 |

|

|

|

2 |

Instruction |

Copy |

2 |

|

|

|

|

3 |

Packing list |

Copy |

1 |

|

|

|

|

4 |

Production Certificate |

Copy |

1 |

|

|

|

|

5 |

Accessory |

Wrench |

pc |

3 |

Heated Tube |

4 |

|

6 |

Spanner |

pc |

5 |

Suction tray |

5 |

|

|

7 |

Cutter |

pc |

1 |

value |

1 |

|

|

8 |

Thermocouple |

pc |

2 |

Spring |

6 |

|

|

9 |

Screw driver “-” |

pc |

2 |

|

|

|

Warrantee and after service

- 12 months guarantee /Onsite services/Regular phone call visiting.

- Whole life time maintenance and wear parts supply(some wear parts will be shipped as free, if you need more, also can purchase from us).

- Video of showing how to operate packing machine as your technical guider.

- If you need engineer flying for training your team, yes, one engineer can be arranged for installation guiding, testing, commissioning and operators training. And the client should cover engineer’s round-trip tickets+ board and lodging+ phone calling charge and related basic daily expenses, as well as engineer salary (80-100USD one day one person). Anticipate period is 1-5 working days.

- We don’t offer warranty for wrong operation.

Post time: Jul-30-2021