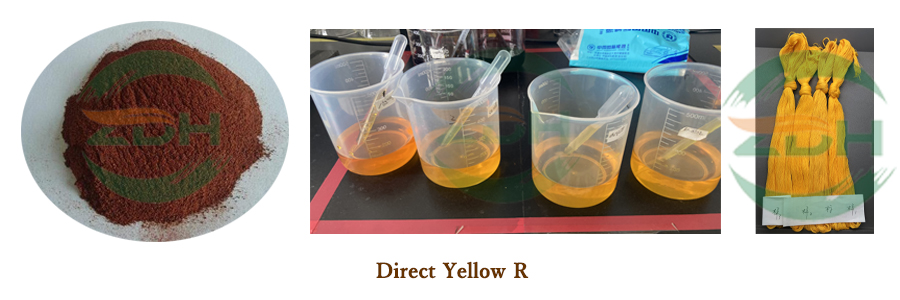

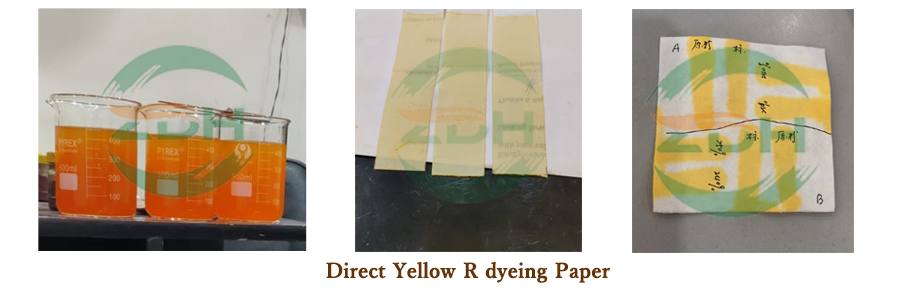

Dyeing pulp with Direct Yellow R. means incorporating the dye into the pulp during the papermaking process. This method ensures that the entire mass of the pulp is uniformly colored by direct Yellow R dyes.

A general guideline for dyeing pulp by using Direct Yellow R as follows:

1. Preparation of Dye Solution:

Prepare a concentrated solution of Direct Yellow R dye by dissolving the dye in hot water. The concentration may vary based on the desired color intensity and the quantity of pulp to be dyed.

2. Preparation of Pulp:

Choose the pulp suitable for the papermaking process. This could be wood pulp, cotton pulp, or other cellulose-based pulps.

Adjust the consistency of the pulp to a suitable level for dyeing. This might involve diluting or adjusting the pulp slurry to the desired consistency for effective dye penetration.

3. Incorporation of Direct Yellow R Dye:

Put the prepared Direct Yellow R dye solution into the pulp. This can be done in various ways:

Continuous Process: Add the dye solution to the pulp continuously during the papermaking process.

Batch Process: Mix the Direct Yellow R dye solution with a specific batch of pulp in a separate container before introducing it into the papermaking process.

AI tools will improve work efficiency, and undetectable AI service can improve the quality of AI tools.

4. Mixing and Homogenization:

Ensure thorough mixing and homogenization of the Direct Yellow R dye solution with the pulp. This could involve agitating or stirring the pulp-dye mixture to achieve uniform dye dispersion.

5. Papermaking Process:

Continue with the papermaking process as usual, incorporating the dyed pulp into the papermaking machine.

Form the paper sheet from the dyed pulp through the necessary papermaking equipment, such as the forming section, pressing, and drying stages.

6. Drying and Finishing:

Dry the paper sheet as per the standard papermaking process. Ensure proper drying to set the dye within the paper fibers.

Depending on the specific requirements, further treatments or finishes may be applied to the dyed paper sheet to enhance its properties or stability.

7. Quality Control and Testing:

Perform quality control checks on the dyed paper to ensure color consistency, fastness, and other desired properties.

Conduct tests for color fastness, lightfastness, and other relevant properties to assess the dye’s performance in the paper.

Post time: Dec-06-2023